Skanska was part of the triventure, which also included its sister company Tidewater Skanska, that was awarded this $768 million contract to renovate and seismically retrofit the Richmond-San Rafael Bridge in California.

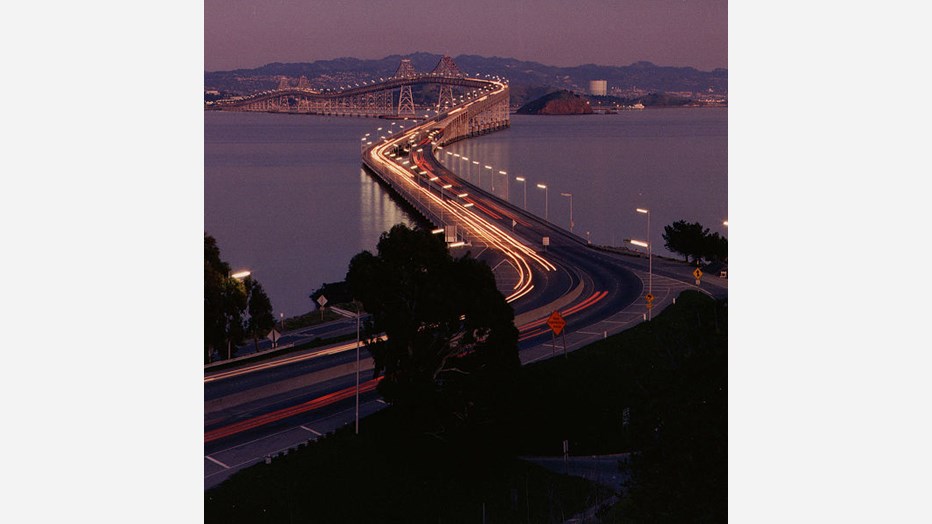

The 4.5-mile-long Richmond-San Rafael Bridge is part of Interstate 580 spanning the City of Richmond and the City of San Rafael. The structure is one of seven that are included in Caltrans’ (California Department of Transportation) seismic retrofit program.

The contract consisted of major renovations and seismic retrofitting of both the superstructure and foundation. The Richmond-San Rafael Bridge is one of the largest and most complicated bridges in the state. Factors such as: variable soils and foundations, aged and complex structures, heavy traffic volume, utilities, shipping concerns and environmental issues combine to make this project extremely challenging.

Major components of work at the site included: traffic handling, grading and paving, contractor access, utilities/highway facilities and handling of hazardous contaminated material. Since the bridge carries over 60,000 vehicles per day, two lanes of traffic in each direction remained open during peak traffic hours. Construction activities occurred around live traffic.

Because several sensitive species of wildlife live near and around the bridge, the client was particularly concerned that any team chosen for this project be attentive to the needs of the animals. Harbor seals, double-crested cormorants, winter run chinook salmon, Pacific herring, peregrine falcon and eelgrass are all inhabitants of the immediate area in which work had taken place. During times when species were spawning or nesting, work was not permitted in those respective areas. Concerns of this nature required close coordination and scheduling with local officials.

The Seismic Rehabilitation of the Richmond San Rafael Bridge consisted of multiple types of steel and concrete retrofits for this 4 mile long steel structure. Over 5,000 tons of retrofit steel was installed in the superstructure involving the removal of 250,000 rivets and field drilling over 500,000 holes for new high strength bolts. The structural steel portion of the substructure work involved the erection of over 10,000 tons of structural steel in the form of new moment frames and eccentrically braced frames (EBF’s). Individual pieces ranged over 100 tons and over 150 feet in length. Pieces were preassembled off site and delivered by barge to be erected either with strand jacks or barge mounted cranes.