The world’s most modern research facility

Skanska is building what will be a cross-discipline research facility based on the world’s most powerful neutron source. European Spallation Source, ESS, will help improve everyday life for many people. Researchers worldwide will be able to study future materials in detail here. ESS is located in Lund, Sweden.

Skanska was responsible for constructing the buildings and infrastructure for the research facility. In December 2021, Skanska handed over all buildings to ESS. The work was carried out as a collaboration project, which means that Skanska and ESS worked together using an open and integrated approach. Together we deliver a world-leading facility that has the opportunity to change the world. The research facility will be fully operational by the end of 2027.

A joint European research facility

ESS is a joint European research facility to which 13 member countries contribute technical equipment, expertise and funding. This is a so-called spallation facility, which means that protons are are accelerated to almost the speed of light in the plant's accelerator tunnel. When the protons collide with the target, a rotating helium-cooled wheel, neutrons are released and led to the experimental stations in long glass tubes.

The instruments at the facility can be compared to gigantic microscopes that permit the study of materials at the molecular and atomic levels. It will be possible to use the facility in a series of sciences such as medicine, biology, chemistry, physics and technology.

More than 500 people will work at ESS when it is fully operational. The facility will become a meeting place for researchers from all over the world and is expected to attract 3,000 researchers annually who will visit ESS to carry out their experiments. Relations will be established that provide development opportunities for business, both regionally and nationally. The research at ESS will contribute to solving major challenges in our society and lead to many exciting results in material research, renewable energy, biomedicine and pharmaceuticals.

Skanska's assignment

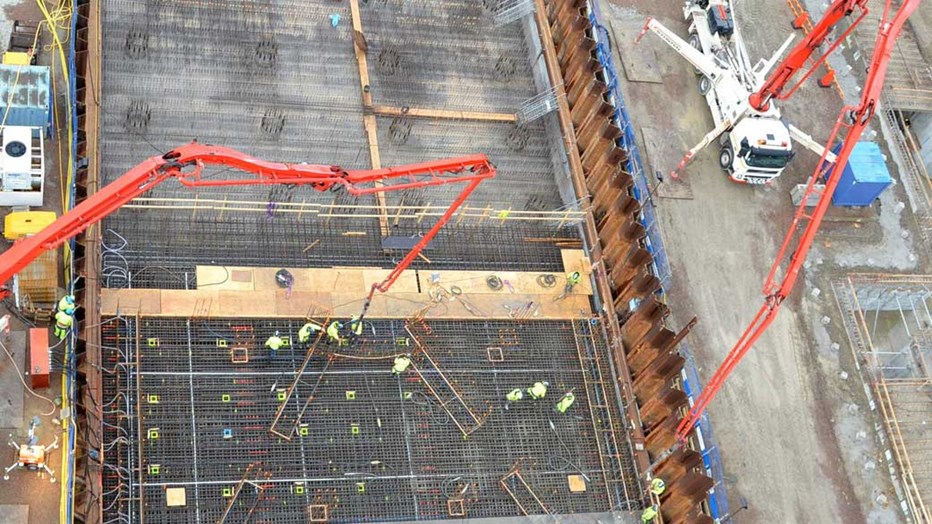

Skanska was responsible for planning and building the shell and infrastructure of the research facility together with ESS. The assignment included planning and building an approximately 500 meter long accelerator tunnel, a target station, three instrument halls and service buildings. In addition, Skanska was also responsible for roads, cables, groundwork and plantings.

Construction process

In order to have an efficient construction process and at the same time enable ESS to be built with the latest technology, Skanska and ESS worked in close collaboration where planning was carried out in stages. Separate agreements were made at the beginning of each stage. Skanska contributed with expertise in the planning and project work; ESS contributed with experience in the construction organization.

Construction work on the 70-hectare ESS site commenced in 2014, but the planning work for this advanced facility started much earlier and was completed in December 2021. Already in 2017, Skanska began handing over parts of the facility through early access, in order to enable ESS to commence installation and testing of technical equipment and instruments. 1000 people worked at the construction site during the busiest phase of the project.

Sustainable and energy-efficient research facility

Not only will ESS become one of the world's most modern research facilities, it will also be one of the most sustainable and energy smart research facilities.

The ESS energy concept is based on three pillars: the plant will be very energy efficient and will use as little energy as possible, all energy will come from renewable energy sources and the waste heat will be recycled.

Excess heat to be recycled

An important part of the sustainability work is the innovative reuse of excess heat from the research facility. Most of the waste heat will be recycled and used for heating the plant's various offices and buildings as well as the new low temperature district heating network in the surrounding area, but above all in Lund's existing district heating network. ESS thus contributes to reducing carbon dioxide emissions in Lund and the surrounding area, while lowering the plant's operating costs.

The most important and long-term environmental and sustainability impact of ESS is the future applications of the research results that the facility enables.

ESS phases

- Construction 2014-2027

- ESS Campus inauguration in March 2021

- Initial operation 2023-2027

- Full operation 2028