From a match to a concert within an hour

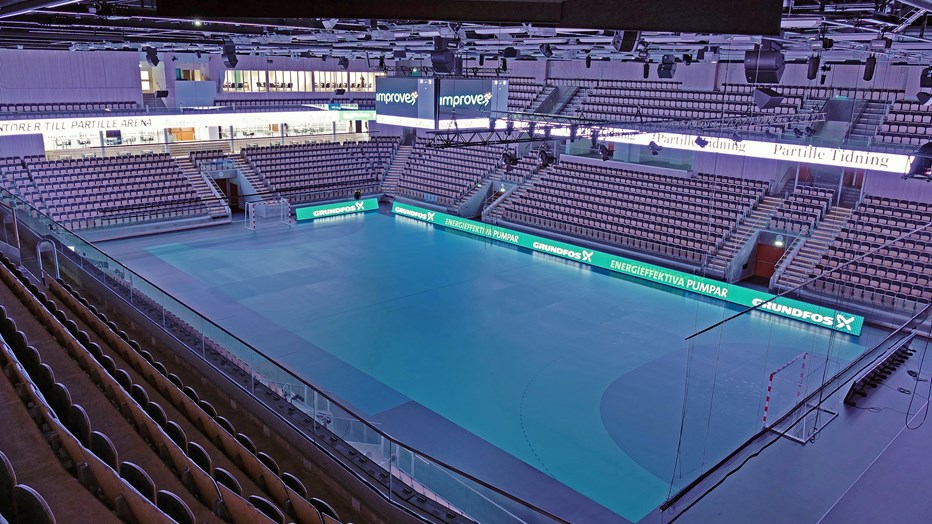

Partille, near Gothenburg, is growing fast. Here, we have built Sweden’s first multifunctional arena, a flexible facility that can be quickly rearranged from housing a handball match during the day and hosting a music concert in the evening. With seating for 4,000 spectators, Partille Arena is a medium-sized facility, and a significant complement to the giant Scandinavium and Ullevi arenas.

In October 2013, project engineering began for the Partille Arena and in December the same year, 500 six-year-olds turned the first sod. Their enthusiasm mirrors the project: All those involved in the Partille Arena felt that this is a type of project that one is involved with just once in a lifetime.

Skanska won the assignment through a public tender, thanks to a cost-conscious proposal that met all functionality requirements. The project was a turnkey contract, and the client was Partillebo, the municipality’s property company. Many competencies within Skanska were involved as a result of the facility’s size and complexity.

The arena is the home ground for the successful handball club, IK Sävehof, but the facility is for everyone. The 18,700 square-meter area is used by school, association and elite sports. In addition to training sessions and matches, this is also the site for concerts and other cultural events. The arena also houses restaurants, bowling, gym, workshops for operating personnel, conference premises and offices.

In January 2014, we began to decontaminate the old industrial site. Luckily, the ground was less contaminated than expected, permitting us to move rapidly on to site preparation work.

Vibrations from “bouncy” spectators

An arena must cope with vibrations from bouncy spectators. We conducted a detailed dynamic analysis and elected to use point-bearing concrete piles. The upper part of the ground is clay, which is common in the Gothenburg area. After this, there is non-cohesive soil consisting of stone or gravel, and furthest down there is rock. We set the piles in the non-cohesive soil so that they form a firm foundation for the arena.

But it isn’t just the arena that is significant in terms of vibrations. The houses built nearby may be built in a manner that reinforces or dampens the vibrations from the arena. This is a matter of the rigidity of the building. We calculated various data that presented builders with the conditions to ensure that they could construct buildings in the correct manner.

Highway entails requirements for the framework

The next step was to lay a concrete base. Subsequently, we built the framework. The nearby E20 highway imposes certain requirements in respect of the framework. This highway is used to transport hazardous goods, such as petroleum and diesel. We have dimensioned the building to cope with any explosion.

– The building reflects a special design, like a loaf of bread. The section that faces the highway is a concrete wall that then transforms into an arch-shaped roof. We’ve designed the walls and roof to ensure that they can cope with an explosion, says Jonas Jonsson, Project Manager.

Non-disturbing operations

The required flexibility of the building was a test for the designers. All the operations in the building impose different requirements in terms of design, sound, ventilation and lighting. The requirements are quite frequently conflicting, so you have to find the optimal solution. A concert may be held in the main auditorium, while people sit and work in the office section. An important bowling match and handball training must never disturb each other.

Electrical installations

An arena requires a great deal of electrical installations. Apart from audio-video, there is also the matter of fire alarms and burglar alarms. Everything must function in the optimal manner.

We have worked closely with architects and subcontractors to find optimal solutions. All parties were encouraged to express their opinions at an early stage so that we could gain from their experience.

Flexibility is more than activities in various halls not interrupting each other. It also involves the capacity to rapidly convert a space from one event to another. During the day, people can watch a Sävehof game; subsequently, on the same day, the seating is removed and placed in front of the stage for a performance by Kulturskolan (Culture Academy). This has created an affinity between the spectators and performing artists.

In September 2016 the arena was inaugurated and the Partille population gained access to their new rendezvous; a living arena and a landmark in this expanding municipality.

Safe working environment

Skanska always focuses on a safe work environment. Jonas Jonsson explains how safety programs have resulted in other positive effects:

– The most important factor is the safety of the workers. We don’t want any workplace accidents. Now we’re beginning to see other positive effects of safety work. Our efforts in the areas of work preparation and risk inventory offer more efficient work methods and superior planning.

Green workplace

The project was a green workplace, which is our own environment labeling designed to reduce environmental impact during the building process. For example, we recycle at least 95 percent of waste, have fast-flow faucets and use work vehicles in an economic manner.

Cooperation and pride

The cooperative spirit was very strong in this project: all the players involved felt proud to be involved in creating this arena. The municipality, the property company, sub-contractors and Skanska worked closely together to find the best solutions. Many competencies within Skanska were involved, since it was a major project imposing unique requirements.